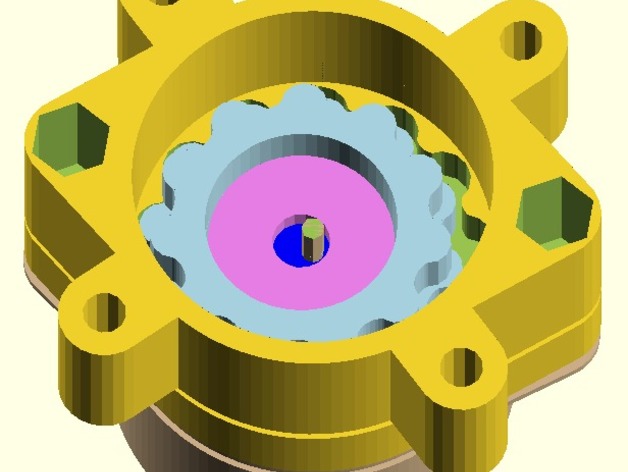

This is a differential cyclodial gearbox which achieves a large ratio by a similar mechanism to the "split planetary" gearbox, but with far fewer and much less delicate parts.

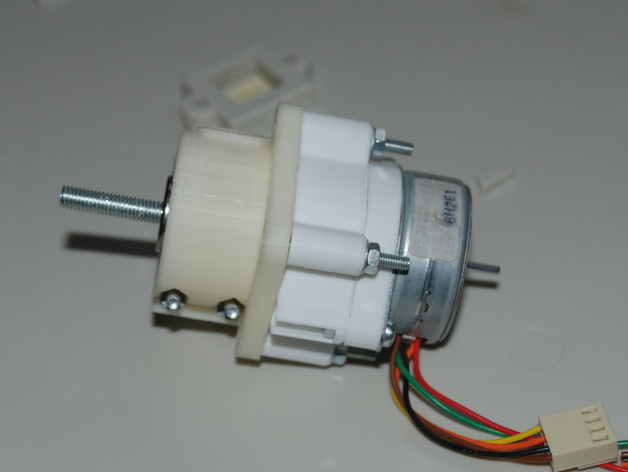

With this large a gear reduction ratio, small & light "tin can" or "pancake" stepper motors, usually considered useless, may be useful for things like extruders. This one is designed to fit a PF-35T-48L4 motor I got from salvage. (Very similar one on SparkFun )

I did not want to put four little, fragile pins on the inside of the gear as pictured in most cycloidal solutions. It is designed so that the output is co-axial with the input, letting everything load-bearing easily sit on ball bearings.

It requires a few vitamins:

The "lemon shaped" mount fits only the pancake motor. The "turtle shaped" mount which sits atop fits the pancake motor with the two side screws and a NEMA17 flange with the other four. It is pictured attached to my Kossack extruder.

Not certain this formula is perfect, though it works for the situations I use it.

My design has 13 and 12 teeth on the lower gears, 12 and 11 teeth on the upper, which works out to 144:1.

Name Last modified Size Description

Parent Directory -

hypo35.scad 2017-01-09 20:24 12K Complete Source Code

hypo35.jpg 2016-01-19 10:59 49K 144:1 Hypocycloid Gearbox

hypo35-turtle.stl 2016-02-23 09:10 288K Midsection fitting NEMA17

hypo35-shaftpin.stl 2016-02-23 09:10 15K Eccentric pin driven by motor

hypo35-out.stl 2016-02-23 09:10 241K Output Gear

hypo35-ecc.stl 2016-02-23 09:10 394K Eccentric driven by bearing

hypo35-base.stl 2016-02-23 09:10 258K Base which fits PM35 motor

hypo35-assembled.jpg 2016-01-19 10:56 54K 144:1 Hypocycloid Gearbox

dual-cycloid-ratio.gif 2016-02-04 10:18 941 Gear Ratio Formula

cyclo.pl 2017-01-10 16:41 274 Perl code to calculate ratio