|

Finally, I found what I needed! The original container idea, a coffee-can with a spindle inside it, turned out to be a bad idea... among other things, the insulation would crush the spindle; and having to punch the cooling apparatus through four layers of insulation, plastic, and metal was just begging for trouble. For a long time I looked for a suitable cooler at garage sales and stuff until I gave up and just got this from Canadian Tire. |

|

A perfect fit! And doesn't that look well-insulated already? |

|

The CDR spindle needed a bit of trimming before it would fit, but fit it did. |

|

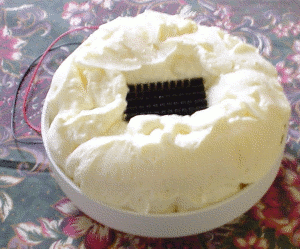

Marking out the top cutout for the the peltier element. |

|

It fits! |

|

Sandwiching the heatsink assembly around it. There's two heatsinks, one inside, one outside. held together with four machine screws. The plastic was thinner than the peltier device, so it wasn't sandwiched all that securely, but the next step gooed everything into place. |

|

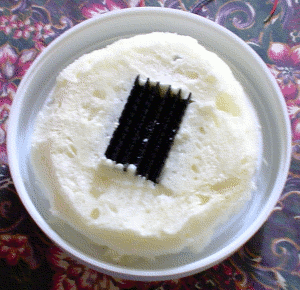

Sealing and insulating the inside of the otherwise bare plastic lid. It looks like some sort of robotic pie. When come back, bring pie. |

|

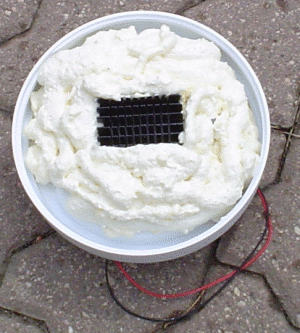

BOY does that stuff swell a lot. |

|

The foam, fully set and cut to the shape I want it. |

|

Test-fitting the lid. It still fits right. |

|

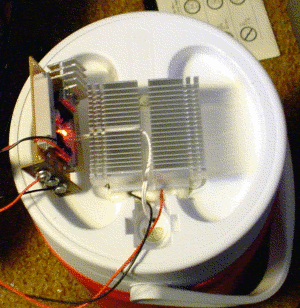

Hooked up circuit v1.0.0. You can see the

thermistor leads going through the hole where the spout used

to be. But BOY is it running hot. Most of the heat is being generated by the circuit's heatsink, not the cooler's heatsink, and I do not know why. I'll have to try constant-current tests of the peltier to make sure it's actually doing it's job. I suspect it is though, since the inside peltier wasn't warm -- wasn't cold, either, but wasn't hot. |

| Back to cdcool | |

|---|---|